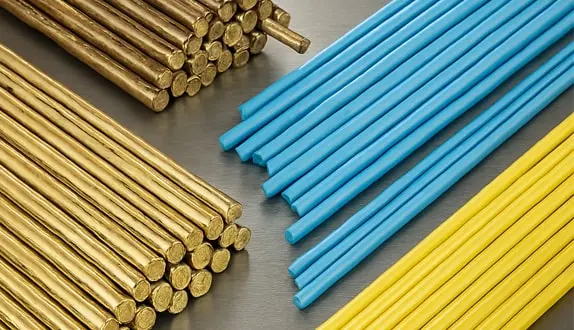

Tungsten Carbide Tools Tipped GradesBrazing

DESCRIPTION & APPLICATIONS :

These general-purpose alloys provide excellent mechanical strength and good wetting, making them ideal for brazing hard metals to steel mountings.

Special compositions with added elements enhance performance:

- Nickel – improves corrosion resistance and brazing of difficult materials (stainless steel, tool steel, tungsten carbide, nickel alloys).

- Manganese – enhances carbide brazing.

- Zinc-free alloys – suitable for furnace brazing and wet conditions (prevents interfacial corrosion).

Tungsten Carbide Tools Tipped Grades

| Superon Ag Brazing Alloy | Normal Composition % | Operating Temp | Shear Strength | International Standards | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ag | Cu | Zn | Ni | Others | °C | MPa | IS 2927 | DIN EN 1044 | BS 1845 | AWS A5.8 | DIN 8513 | |

| SUPERON Ag 50N | 50 | 16 | 15 | 3 | Cd 16 | 645 | 150-300 | BACuAg12 | Ag351 | Ag9 | BAg-3 | L-Ag50CdNi |

| SUPERON Ag 49Hi(MnNi) | 49 | 16 | 23 | 4.5 | Mn 7.5 | 690 | 250-300 | - | Ag502 | Ag18 | BAg-22 | L-Ag49 |

| SUPERON Ag 40N | 40 | 30 | 28 | 2 | - | 730 | - | BACuAg18 | - | - | BAg-4 | - |

| SUPERON Ag 27 | 27 | 38 | 20 | 5.5 | Mn9.5 | 810 | 150-300 | - | Ag503 | - | - | L-Ag27 |

| SUPERON Ag 25MnNi | 25 | 38 | 33 | Ni2 | Mn2 | 790 | - | - | - | - | BAg-26 | - |

| SUPERON NIBRO | - | 50 | 39.7 | 10 | Si 0.3 | 910 | 150-300 | SC9 | Cu305 | CZ 8 | RBCuZn-D | L- CuNi10Zn42 |

| SUPERON CuNiB | - | 97 | - | 3 | Boron 0.03 | 1100 | - | - | Cu105 | CU 7 | - | - |

| SUPERON F BRONZE | - | 57 | 39 | - | Mn2, CO2 | 920 | - | - | - | - | - | - |

General Composition