At Superon Technik, we manufacture high-quality copper-coated mild steel MIG wire designed for stable performance, smooth welding and long-term reliability. As a trusted industry supplier, we offer strong technical consistency, excellent feedability and dependable weld quality for industrial applications across India and global markets.

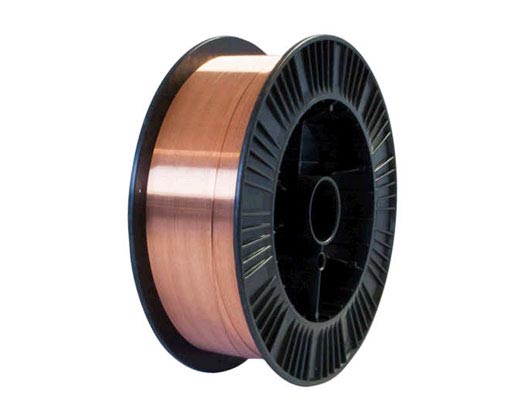

CCMS MIG Welding Wire

Copper-coated mild steel MIG wire is widely used in many fabrication industries due to its stable performance, high productivity and ease of use. This type of MIG welding wire combines the strength of mild steel with a protective copper coating that ensures smooth electrical conductivity and consistent welding performance.

The copper layer helps prevent rust formation and improves current flow, making it ideal for automated welding systems and high-speed applications. As one of the reliable MIG wire manufacturers in India, Superon Technik ensures its mild steel wire is clean, uniform, and designed for steady wire feeding, which is essential for long welding runs and consistent quality.

Using mild steel MIG wire also helps reduce spatter, improve bead appearance and maintain a stable arc, which is why it is preferred for general fabrication, automotive component manufacturing and pressure vessel welding.

About SUPERMIG 70S-6 Mild Steel MIG Wire

SUPERMIG 70S-6 is one of Superon Technik’s premium-grade mild steel MIG wire products designed for high performance across industrial welding applications. This wire is engineered for superb arc stability and trouble-free wire feeding. It produces high-quality welds with minimal spatter and excellent mechanical strength.

This MIG welding wire is copper-coated to improve conductivity and corrosion resistance, enhancing durability during storage and use. The clean surface ensures smooth feeding through torches and machines.

SUPERMIG 70S-6 is suitable for welding unalloyed steels used in automotive parts, construction equipment, pressure vessels, metal structures and shipbuilding. With consistent performance and strict quality control, it stands as a preferred choice for buyers seeking a reliable MIG wire.

Benefits of Copper-Coated MIG Welding Wire

Here are the key benefits of copper-coated MIG welding wire:

- Excellent conductivity for stable arc performance

- Corrosion-resistant copper coating for long wire life

- Reduced spatter for cleaner weld beads

- Smooth and reliable wire feeding in manual and robotic welding

- Improved weld penetration with strong mechanical properties

- High-quality copper coating ensuring minimal drawing residue

- Suitable for continuous production environments

These advantages make Superon’s copper-coated MIG welding wire dependable for professional fabrication. Many choose this premium mild steel MIG wire because it delivers both quality and efficiency across automated and manual welding setups. The wire is durable, consistent and trusted by industrial users nationwide.

Applications of MS MIG Wire

Our mild steel wire is widely used across many sectors because it offers strong weld integrity, fast production output, and stable performance.

Key industries and applications:

Automotive: Used for body frames, seat frames, exhaust systems and component fabrication. The wire provides uniform weld quality and fast cycle times, making it ideal for automotive production lines.

Fabrication Workshops: Suitable for manufacturing metal structures, gates, frames and machine parts. It ensures reliable performance for daily welding tasks.

Construction: Used for steel reinforcements, structural beams and building supports. The wire provides strong joints and predictable weld behaviour on mild steel.

Pipelines: Used for welding pipes and fittings in low-pressure applications. It supports smooth penetration and stable weld pools.

Heavy Engineering: Used in equipment manufacturing, pressure vessels and industrial machine construction. The wire performs well in demanding projects that require strength and precision.

These real-world applications show how dependable MIG welding wire can improve productivity and welding efficiency in both small and large projects.

Solid MIG Wire Grades and Specifications We Offer

We manufacture high-performance SUPERMIG 70S-6 in a wide range of sizes and packing options to meet varied industrial needs.

Key specifications:

- Product Name: SUPER MIG 70(S)

- Classification: AWS/SFA ER 70S-6

- Yield Strength N/mm2: ≥ 450

- Tensile Strength N/mm2: ≥ 510 to 640

- Elongation A5 (%): ≥ 26

- Impact Energy at -30°C: ≥ 47 J

- Welding Conditions: DC (+)

Packing options:

- SD 300 / BS 300: 11.34 kg, 15 kg, 25 lbs, 30 lbs, 33 lbs plastic or metallic spool

- SD 200: 4.54 kg, 10 lbs spool

- SD 100: 0.700 kg, 0.910 kg, 2 lbs spool

- Drum Packing: 100 to 250 kg drums

These options make it easier for buyers to choose the right MIG wire 70S-6 for their needs, whether they require small spools for workshops or large drums for automated production lines.

The wire meets international mild-steel welding wire specifications and ensures uniform chemical composition and stable mechanical properties.

Why Choose Superon Technik for MIG Welding Wire

Superon Technik is recognised as one of the leading MIG wire manufacturers in India due to its strong focus on quality, customer support, and product consistency. Manufacturers, fabrication units, and welding professionals trust the brand for its proven performance in challenging environments.

Key reasons:

- High-purity wire with ultra-clean surface

- Reliable product quality backed by international standards

- Advanced manufacturing and inspection facilities

- Strong supply chain for timely delivery across India

- Technical support for product selection and welding guidance

- Experience in serving the automotive, heavy engineering, fabrication, and pipeline sectors

As a reliable supplier of mild steel MIG wire, we ensure that each batch delivers the same consistency and weld quality. Buyers looking for MIG welding wire in India rely on Superon Technik for both large-scale and specialised welding requirements.

-

What is copper-coated MIG welding wire?It is a mild steel welding wire coated with copper to improve conductivity, corrosion resistance and smooth feeding performance.

-

Why use mild steel MIG wire instead of MS stick electrodes?MIG wire provides faster welding speeds, less spatter, smoother weld appearance and higher productivity compared to stick electrodes.

-

Which industries use mild steel MIG wire?The automotive, construction, fabrication, pipeline, heavy engineering and shipbuilding industries commonly use this wire.

-

How do I select the right MIG wire diameter?Choose based on base metal thickness, welding machine capacity and required penetration depth. Thicker wires suit heavy sections, while thinner wires suit sheet metal.

-

What are the advantages of copper-coated welding wire?Some key advantages include better conductivity, strong corrosion resistance, smooth wire feeding, reduced spatter and stable arc performance.

-

Which classification does SUPERMIG 70S-6 cover?SUPERMIG 70S-6 meets the AWS/SFA 5.18 ER70S-6 classification.