Abrasives play a crucial role in shaping, cutting, and polishing materials across industries like metal fabrication, construction, and automotive manufacturing. From grinding wheels to polishing pads, high-quality abrasives ensure precision, efficiency, and durability in every application.

SuperonTechnik – Leading Abrasive Supplier in India

SuperonTechnik is a leading name in abrasive supplier, known for producing superior-quality grinding and cutting tools. Serving industries such as metalworking, automotive repair, shipbuilding, and construction, we combine years of expertise with advanced production facilities to deliver reliable, high-performance abrasives.

Our Range of Abrasive Products

Superon offers a wide range of abrasives made for cutting, grinding, polishing, and finishing. Each product is made with precision using top-grade materials to ensure maximum durability and consistent results.

Thin Cutting Wheels

SuperOrange Thin Cutting Wheels are available with single- or double-reinforcement in thicknesses of 1–2 mm. They are designed for general-purpose cutting and can handle a wide range of materials, including MS, copper, aluminium, and plastic, cutting them in half the time it takes with conventional wheels.

Key Benefits:

- Faster cutting with reduced time

- Minimal burn and burrs

- Lower power consumption

- Reduced operator fatigue

Large Dia Cutting Wheels

SuperOrange Large Diameter Cutting Wheels are available with single- or double-reinforcement combinations to suit different applications. They are designed for fast and precise cutting of pipes, angles, and channels of all kinds.

Key Benefits:

- Efficient and smooth cutting on various materials

- Reduced cutting time and effort

- Durable performance with minimal wear

- Safer operation with less risk of wheel damage

Grinding Discs

SuperOrange Grinding Discs are specially designed for weld grinding and notching applications, delivering top-tier performance and excellent value.

Key Benefits:

- Smooth and precise grinding for clean finishes

- Durable design for longer life

- Efficient material removal, saving time and effort

- Consistent performance across various metals

Flap Discs

SuperOrange Flap Discs, also known as flapper wheels, are designed for use with right-angle grinders. They offer versatility, delivering aggressive stock removal or precise blending and finishing based on the operator’s requirements.

Key Benefits:

- Efficient material removal for faster work

- Smooth finishing and blending for polished results

- Durable construction for long-lasting performance

- Versatile for multiple applications and metals

Felt Buff Pad

SuperOrange Felt Buff Pad is designed for polishing hard materials such as steel. Its highly aggressive, rapid-action pads deliver precise and well-defined polishing results.

Key Benefits:

- Fast and efficient polishing

- Produces smooth, accurate finishes

- Ideal for hard materials like steel

- Durable design for consistent performance

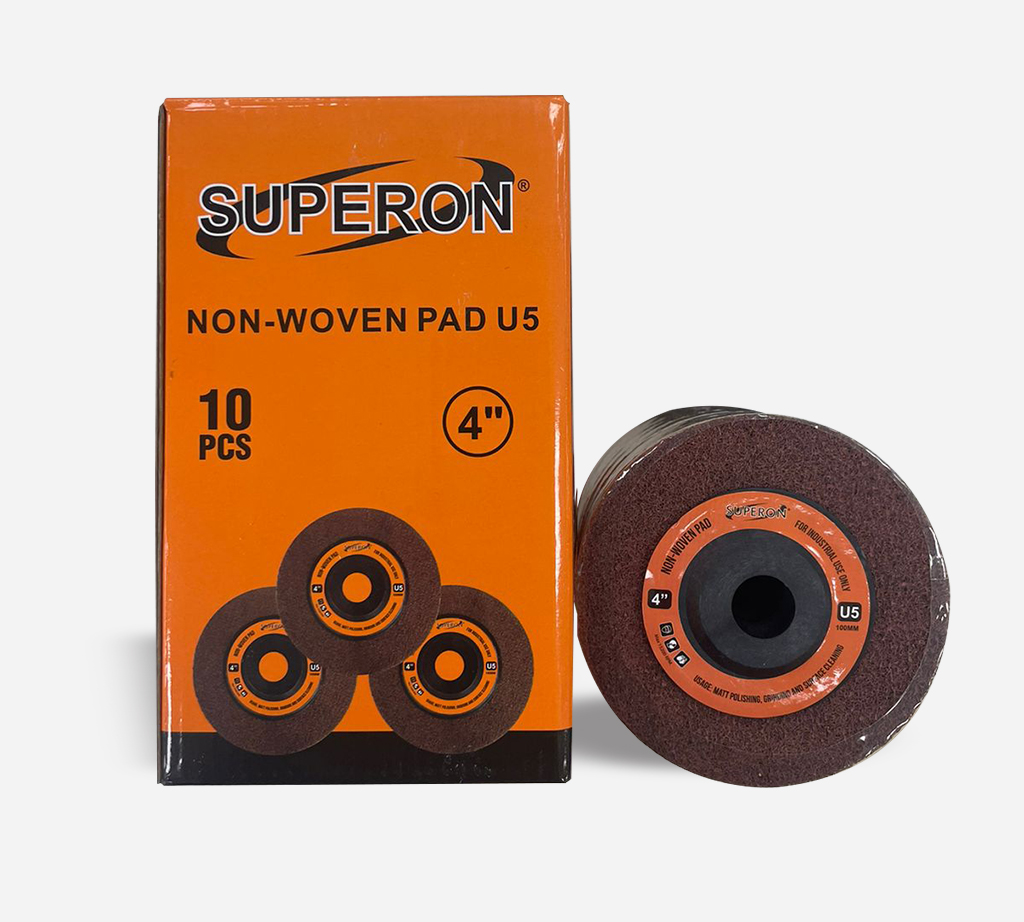

Non-Woven Pads

SuperOrange Non-woven Discs are designed for blending and polishing applications, providing effective surface conditioning without damaging the underlying material. They offer a versatile solution suitable for multiple industries.

Key Benefits:

- Smooth and consistent surface finishing

- Effective blending and polishing of various materials

- Gentle on the underlying surface to prevent damage

- Versatile for use across different industries

Core-Bit

Superon Core Bits are engineered for fast and efficient cutting through concrete, asphalt, and marble. They are built for durability, offering long-lasting performance even under demanding conditions.

Key Benefits:

- Fast and precise cutting on hard surfaces

- Long-lasting durability and endurance

- Suitable for concrete, asphalt, and marble

- Reliable performance in heavy-duty applications

Welding Electrode Holder

Superon Electrode Holders are crafted with high-quality materials using advanced manufacturing techniques to meet the rigorous demands of the welding industry.

Key Benefits:

- Durable construction for long-term use

- Reliable performance under heavy-duty conditions

- Comfortable and safe handling for operators

- Designed to withstand demanding industrial environments

Superon Abrasives are designed to meet the evolving demands of modern manufacturing, ensuring reliability and precision in every task.

Types of Abrasive Wheels and Their Applications

Abrasive wheels come in different types, each serving a specific purpose depending on the surface and desired finish.

1. Bonded Abrasives

Bonded abrasives include grinding and cutting wheels where abrasive grains are fused with bonding materials like resin or rubber.

- Used for cutting, deburring, and metal shaping

- Common in foundries, fabrication, and construction

2. Coated Abrasives

These have abrasive grains attached to flexible backings like paper or cloth, such as sandpaper or flap discs.

- Used for finishing, polishing, and surface preparation

- Suitable for wood, plastic, and metal

3. Non-Woven Abrasives

Made from synthetic fiber mesh impregnated with abrasives, these pads are used for light cleaning and finishing.

- Delivers consistent finishes without damaging surfaces

- Used in stainless steel finishing and maintenance applications

Each type of abrasive wheel is selected based on the hardness of the material, surface texture requirements, and working environment.

Applications of Our Abrasive Tools & Products

Our Abrasives are widely used across industries for cutting, grinding, polishing, and finishing applications.

- Metal Fabrication: Cutting and grinding metal sheets, pipes, and structures

- Automotive Industry: Surface finishing, paint removal, component polishing

- Construction: Concrete cutting, shaping, and leveling

- Shipbuilding: Rust removal, weld grinding, hull maintenance

- Aerospace: Precision finishing and metal cleaning

- Woodworking: Smoothing and shaping wooden components

- Manufacturing: Tool sharpening, mold cleaning, component preparation

Why Choose SuperonTechnik as Your Abrasive Supplier

Choosing the right abrasive wheel supplier can make all the difference in performance and productivity. Superon Technik stands out for its quality, innovation, and reliability. Here’s why customers prefer us:

- Proven Expertise: Years of experience serving industrial clients

- Advanced Technology: Modern facilities ensure consistent quality

- Wide Product Range: From thin cutting wheels to non-woven pads

- Durability & Performance: Long-lasting, high-output abrasives

- Customer-Centric: Custom solutions tailored to your needs

- Trusted by Industries: Preferred by professionals in automotive, construction, and metal fabrication

-

What types of abrasives does Superon supply?Superon supply cutting wheels, flap discs, non-woven pads, felt buff pads, and other industrial-grade abrasives for cutting, polishing, and finishing applications.

-

How to choose the right abrasives for my application?Identify the material you're working on and the finish you want. Harder abrasives are ideal for metals, while softer abrasives are suitable for polishing and fine finishing.

-

What materials are your abrasives suitable for?Our abrasives work effectively on stainless steel, mild steel, aluminum, concrete, stone, and wood.

-

What standards do your abrasive products comply with?All Superon products meet global quality and safety standards for industrial performance, including ISO and ANSI guidelines.

-

Can Superon supply customized abrasive solutions?Superon offers customised abrasive solutions based on grit size, hardness, and specific industrial applications.

-

Difference between bonded and coated abrasives?Bonded abrasives are solid, compact tools like grinding wheels, while coated abrasives are flexible, like sandpaper and flap discs.

-

How do stainless steel abrasives differ from others?Stainless steel abrasives are formulated to prevent contamination and provide a clean, rust-free finish, making them ideal for fabrication and polishing.