Copper and Brass Brazing AlloysBrazing

DESCRIPTION & APPLICATIONS :

Copper-zinc filler metals are widely used in flame, induction, and resistance brazing, suitable for copper, copper alloys, steels, cast iron, and cemented carbide. Clean surfaces and proper flux are essential for strong joints.

General Purpose Brasses, Nickel-Added Brasses, High-Temperature Copper Alloys (special applications), Copper for Furnace Brazing.

These alloys are cost-effective alternatives to silver brazing alloys, offering high strength, good corrosion resistance, and excellent thermal/electrical conductivity.

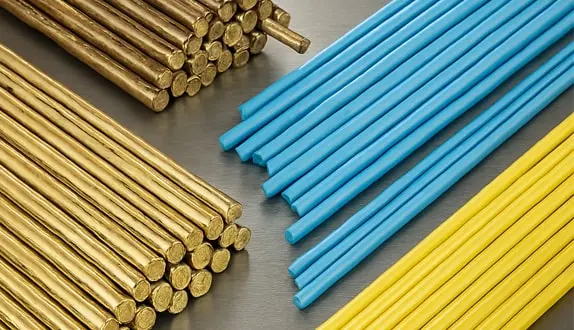

Available in rods, wires, preforms, and flux coating rods.

Copper and Brass Brazing Alloys

| Superon Ag Brazing Alloy | Normal Composition % | Operating Temp | Shear Strength | International Standards | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cu | Zn | Si | Others | °C | MPa | IS 2927 | DIN EN 1044 | BS 1845 | AWS A5.8 | DIN 8513 | |

| SUPERON SIBRO | 60 | 39.6 | 0.4 | - | 880 | Sc6 BACuZn4 | Cu301 | CZ6 | - | L-CuZn40 | |

| SUPERON MANBRO | 60 | 39.6 | 0.2 | Mn 0.2 | 910 | SC8 | - | - | - | - | |

| SUPERON TINBRO Low Sn | 93.8 | - | - | Sn 6 P 0.2 | 1040 | - | Cu201 | - | - | L-CuSn6 | |

| SUPERON TINBRO Hi Sn | 87.8 | - | - | Sn 12 P 0.2 | 990 | - | Cu202 | - | - | L-CuSn12 | |

| SUPERON CUPRO | 100 | - | - | - | 1085 | SC1 BACu1 | Cu102 | - | BCu-1 | L-Cu | |

| SUPERON 680 | 58 | 39.4 | 0.1 | Ni 0.6 Mn 0.3 Sn 1.00 Fe 0.6 | 882 | - | - | - | RBCuZn-B | - | |

| SUPERON LOW FUMING BRONZE | 59 | 39.5 | 0.1 | Sn 1 Mn 0.4 | 870 | - | - | CZ 7A | RBCuZn-C | L-CuZn39Sn | |

| SUPERON BRASS 5545 | 55 | 45 | - | - | 890 | - | - | - | - | L-CuZn46 | |

| SUPERON 470 | 59 | 39.7 | 0.2 | Sn 1 | 890 | - | - | - | RBCuZn-A | - | |

General Composition