Brazing Manufacturer provide the materials and alloys needed to join metals by heating them with a filler metal without melting the base components. They support industries that require clean, strong, and reliable joints for everything from machinery to precision assemblies.

Superon Technik – Industrial Brazing Manufacturer

Superon Technik provides high-quality brazing rods and alloys engineered for precision joining and durability in demanding industrial applications. Manufactured to ISO/AWS standards, our brazing materials deliver consistent performance and reliability, making them the preferred choice across sectors like mining, construction, cement, and metal fabrication.

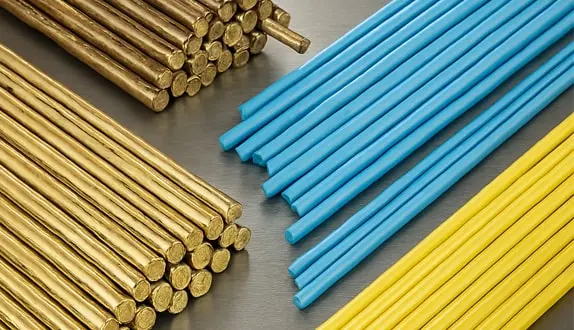

Our Range of Brazing Products

Superon offers a comprehensive portfolio of Brazing solutions tailored to various production requirements and material combinations.

- High Ag Brazing Alloys Cadmium Free Grades:

- High Ag Cadmium Bearing Grades: 0.80mm to 3mm, Cut Rod 1.00 mm to 4.00 mm, length 500/1000mm, as per customer requirements

- Tungsten Carbide Tools Tipped Grades: 0.80mm to 3mm, Cut Rod 1.00 mm to 4.00 mm, length 500/1000mm, as per customer requirements

- Copper and Brass Brazing Alloys

Above Four Family

In Wire Form: 0.80mm to 3mm,

In Cut Rod: 1.00 mm to 4.00 mm, length 500/1000mm, as per customer requirements

In Rings Form: Various size

- Copper - Phosphorus Brazing Alloys

In Wire Form: 0.80mm to 3mm,

In Cut Rod: 1.00 mm to 4.00 mm, length 500/1000mm, as per customer requirements

In Rings Form: Various size,

In Flat Rod Form: W3.15 x T1.27 x L500mm

- Fluxes And Pastes

As a leading Brazing manufacturer, we ensure every brazed joint is produced with the right filler metal, flux selection, heating method, and controlled cooling to maintain mechanical strength.

Types of Brazing Techniques and Their Applications

Different brazing techniques offer different advantages depending on the component design, joint geometry, and material sensitivity. We provide all common Brazing methods with industry-certified accuracy.

High Ag Brazing Alloys Cadmium Free Grades

High Ag Brazing Alloys Cadmium Free Grades are RoHS-compliant, safe to use, and free of cadmium-related health concerns. They are ductile, strong, and free-flowing, available in multiple forms, including rods, wires, rings, preforms, and flux-coating rods. Ideal for joining similar or dissimilar metals, these alloys provide strong, neat joints and are available in various compositions customised for different applications.

High Ag Cadmium Bearing Grades

High Ag Cadmium Bearing Grades are versatile, free-flowing, and high-strength alloys, with some of the lowest melting points among silver-based options. They have been used for decades on a wide range of ferrous and non-ferrous metals and can handle service temperatures up to 200°C. However, their zinc and cadmium content make them unsuitable for stainless steels in wet conditions, and they have been banned in the EU since December 2011 (Reg. No. 494/2011) due to toxicity concerns. They must not be used in applications involving food, beverages, or any area related to human health.

Tungsten Carbide Tools Tipped Grades

Tungsten Carbide Tools Tipped Grades are general-purpose alloys that deliver strong mechanical performance and dependable wetting, making them a good choice for brazing hard metals to steel mountings with clean, durable results. Their stable, consistent flow helps produce uniform joints, even under demanding applications.

Copper - Phosphorus Brazing Alloys

Copper-Phosphorus Alloys are self-fluxing on copper, offering good fluidity, low melting temperatures, and reliable joints without added flux. A flux is required when brazing copper alloys like brass or bronze. Silver-containing grades with lower phosphorus provide better ductility and electrical conductivity. They are widely used in refrigeration, air conditioning, and plumbing. Continuous service temperature is up to 200 °C, with satisfactory corrosion resistance except in sulfurous environments.

Copper and Brass Brazing Alloys

Copper-zinc Filler Metals are commonly used in flame, induction, and resistance brazing, and work well with copper, its alloys, steels, cast iron, and even cemented carbide. Clean surfaces and the right flux are key to achieving strong, reliable joints. Their range includes general-purpose brasses, nickel-enhanced brasses, high-temperature copper alloys for special applications, and copper grades suited for furnace brazing. These materials offer a cost-effective alternative to silver alloys, delivering high strength, good corrosion resistance, and excellent thermal and electrical conductivity.

Fluxes And Pastes

Silver Brazing Fluxes and Pastes come in various formulations, including cadmium, cadmium-free, and induction-ready options. They meet high-temperature requirements for copper and brass and are designed to remove oxides, improve wetting, and ensure strong, reliable joints under varying brazing conditions.

Advantages of Choosing Superon as Your Brazing Manufacturer

We provide advanced Brazing solutions that outperform conventional methods in accuracy, repeatability, and cleanliness.

- Strong joints without melting the base metal

- Ability to join dissimilar metals, such as copper to steel or stainless steel to nickel alloys

- Clean, slag-free, and oxidation-free joints

- Lower power consumption than welding in many applications

- Minimal distortion since the heat is controlled

- High production rates with automated furnace setups

- Retention of base metal mechanical properties

- Smooth finish requiring minimal post-processing

- Ensuring each chemical composition as national and international specification

Applications of Brazing Solutions Across Industries

Our Brazing processes are used across a wide range of industries where accuracy, metal compatibility, and joint reliability are essential.

- Automotive and engine components

- Aerospace heat exchangers and precision structures

- HVAC systems, copper tubing, and refrigeration

- Electrical and electronic components

- Medical instruments and high-purity devices

- Heavy machinery and tool manufacturing

- Oil and gas assemblies

- Defence and marine equipment

- Fabrication shops for specialised metal joining

From small connectors to large engineered structures, brazing supports applications where traditional welding may cause distortion or metallurgical imbalance.

Technical Capabilities of Our Brazing Services

Superon offers advanced technical capabilities that ensure consistent brazing quality:

- Manufacturing brazing alloys through world best technologies and machines

- Support for filler metals such as silver, copper, nickel-based, and specialised brazing alloys

- Ability to braze stainless steel, copper, brass, aluminium, nickel alloys, cast iron, and other metals

- Component size flexibility for both small parts and large assemblies

- Non-destructive testing (NDT) for structural verification

- Precision inspection and thermal cycle control

- In house, Chemical Lab testing facilities

- In house, Mechanical Lab testing facilities

These capabilities ensure that every brazed joint meets the required strength, cleanliness, and performance criteria.

How to Select the Right Brazing Solution for Your Project

Choosing the right brazing method is critical for achieving the desired mechanical strength, cleanliness, and durability.

- Type of base metal and its thermal sensitivity

- Joint complexity and access points

- Required joint strength and operating temperature

- Production volume and cost efficiency

- Tolerance requirements and distortion allowance

- Whether dissimilar metals need to be joined

- Need for oxidation-free or flux-free joints

- Component size and geometry

Our engineering team helps customers evaluate these factors and recommend the most suitable brazing technique and filler metal for optimum performance.

Why Choose Superon Technik for Brazing Solutions

We are well established as a trusted brazing Manufacturer providing precision-engineered brazing alloys, rods, and complete brazing solutions.

Industries choose us because:- We deliver clean, strong, and uniform brazed joints using alloys that meet national and international standards.

- Our filler metals have excellent flow characteristics.

- We maintain global standards in every brazing project.

- Our technicians combine specialised training with extensive manufacturing experience across all brazing methods.

- We manage complex assemblies with ease.

- We ensure quality through every production stage.

- We support custom brazing requirements for specialised components.

Whether you need small-scale torch brazing or aerospace-grade vacuum brazing, Superon ensures consistency, strength, and technical precision.

-

What is brazing, and where is it used?Brazing is a metal joining process that uses a filler metal to bond surfaces without melting the base material. It is used in automotive, electronics, HVAC systems, aerospace, and manufacturing.

-

What types of brazing services does Superon offer?We offer High Ag Brazing Alloys, Cadmium Free Grades, Copper and Brass Brazing Alloys, Tungsten Carbide Tools Tipped Grades, High Ag Cadmium Bearing Grades, Copper - Phosphorus Brazing Alloys, and Fluxes and Pastes.

-

How do I choose the right brazing solution for my component?Selection depends on metal type, joint complexity, strength requirements, and production volume. Superon provides expert guidance.

-

Which industries benefit from brazing solutionsAutomotive, aerospace, HVAC, electronics, fabrication, medical, and heavy engineering.

-

How does Superon ensure quality in brazing processes?Superon ensures quality by manufacturing brazing products in accordance with applicable national and international standards, including AWS, ASTM, ISO, and other industry specifications.

-

Can Superon handle custom brazing projects or specialised alloys?We support custom parts, dissimilar metals, and special alloy requirements.