Copper - Phosphorus Brazing AlloysBrazing

DESCRIPTION & APPLICATIONS :

Copper-phosphorus alloys are self-fluxing on copper, offering good fluidity, low melting temperatures, and reliable joints without added flux. A flux is required when brazing copper alloys like brass or bronze. Silver-containing grades with lower phosphorus provide better ductility and electrical conductivity.

They are widely used in refrigeration, air conditioning, and plumbing. Continuous service temperature is up to 200 °C, with satisfactory corrosion resistance except in sulfurous environments. These alloys should not be used on ferrous or high-nickel alloys due to brittleness risks.

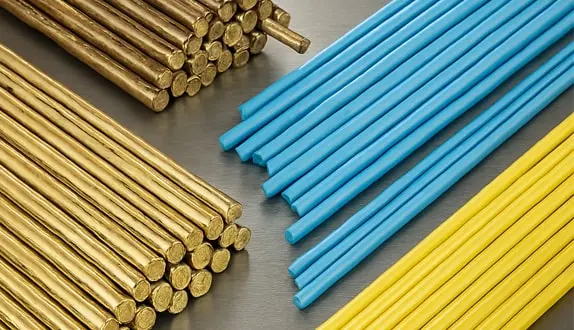

Available in rods, wires, rings, preforms, and granules.

Copper - Phosphorus Brazing Alloys

| Superon Ag Brazing Alloy | Normal Composition % | Operating Temp | Shear Strength | International Standards | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ag | Cu | P | Others | °C | MPa | IS 2927 | DIN EN 1044 | BS 1845 | AWS A5.8 | DIN 8513 | |

| SUPERON Ag 18 P | 18 | 75 | 7 | - | 645 | - | CP101 | - | - | - | |

| SUPERON Ag 15 P | 15 | 80 | 5 | - | 710 | BACuP-5 | CP102 | CP1 | BCuP-5 | L-Ag15P | |

| SUPERON Ag 6 P | 6 | 87 | 7 | - | 700 | - | - | - | BCuP-4 | - | |

| SUPERON Ag 5 P | 5 | 89 | 6 | - | 710 | BACuP-4 | CP104 | CP4 | BCuP-3 | L-Ag5P | |

| SUPERON Ag 2 P | 2 | 91.5 | 6.5 | - | 710 | BACuP-3 | CP105 | CP2 | BCuP-6 | L-Ag2P | |

| SUPERON PHOS. COPPER 1 | - | 92.7 | 7.3 | - | 720 | BACuP-2 | CP202 | CP3 | BCuP-2 | L-CuP7 | |

| SUPERON PHOS. COPPER 2 | - | 93.2 | 6.8 | - | 730 | - | *CuP 180 | - | - | - | |

| SUPERON PHOS. COPPER 3 | - | 93.8 | 6.2 | - | 730 | BACuP-1 | CP203 | CP6 | BCuP-1 | L-CuP6 | |

General Composition