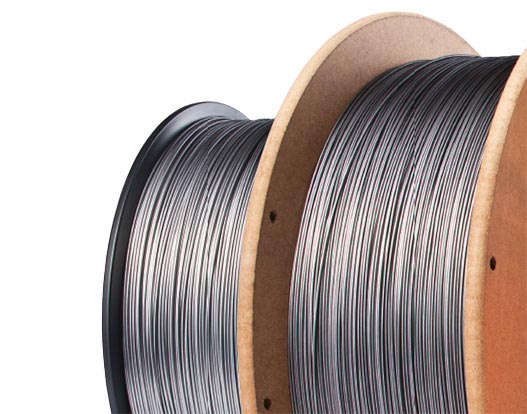

Flux Cored Wires are essential welding consumables used for deep penetration, high deposition rates, and consistently strong welds. They help welders achieve performance, speed, and reliability even in challenging environments. Superon Technik provides advanced Flux-Cored Wire solutions designed for industrial projects that demand strength, corrosion resistance, and high productivity.

What is Flux Cored Wire and Its Advantages

A flux core wire is a tubular welding wire filled with flux compounds in its core that support arc stability, protect the weld pool, and improve penetration. Unlike solid wires, flux core wires provide shielding protection and perform better in thick sections, outdoor environments, and high-stress welding conditions.

Flux core wire is popular because it:

- Provides deeper penetration in thick metals

- Offers a stable arc and smooth weld flow

- Works well in windy and dusty outdoor sites

- Reduces welding time due to high deposition rates

- Supports strong welds even on slightly contaminated surfaces

For industrial welders in India seeking reliability, speed, and quality, Superon Flux Cored Wire solutions are a trusted choice.

Our Range of Flux Cored Wires

We manufacture a complete range of Flux-Cored Welding Wires for various industries and welding applications.

- Super Stanhard OA 32

- Super Stanhard OA 40

- Super Stanhard OA 44

- Super Stanhard OA 50

- Super Stanhard OA 70

- Super Stanhard OA 71

- Super Stanhard OA 72

- Super Stanhard OA 76

- Super Stanhard GS 535

- Super Stanhard GS 9580 MOD

- Super Stanhard OA 600 TIC

Each wire type is engineered for smooth feeding, minimal porosity, and consistent arc performance across varied working conditions.

The Flux Cored Wire and Its Importance

Flux-Cored Wires play a critical role in modern fabrication and industrial welding. They deliver the required strength, speed, and toughness for large-scale projects. Superon's Stainless Steel Flux Cored Wire range is especially important for applications that require corrosion resistance, high heat resistance, and clean finishing.

Industries such as chemical plants, offshore structures, pipelines, pharmaceutical fabrication, and food processing depend heavily on SS Flux Cored Wire because it ensures weld integrity even in extreme environments. These wires support welders who need accuracy, stability, and welds that remain strong under stress.

Applications of FCW in Industrial Welding

Flux-Cored Wires are widely used across multiple industries because they provide strong, reliable, and efficient welds. Key sectors include:

- ShipbuildingLarge steel structures, hull sections, and deck plates require high-penetration and high-strength fasteners. Flux cored wire allows fast welding in indoor and outdoor areas.

- Construction and InfrastructureFrom bridges to high-rise buildings, Flux-Cored Wires support structural welding, heavy fabrication, and field repairs.

- Automotive and RailwaysUsed for body fabrication, chassis repair, and maintenance tasks requiring speed and consistency.

- Oil and GasPipelines, offshore rigs, and refinery structures require corrosion-resistant stainless steel flux cored wire for durability and safety.

- Heavy Machinery and EquipmentIdeal for welding thick plates, repairing machinery components, and fabricating industrial frames.

Benefits of Using Superon Flux Cored Wires

We offer Flux-Cored Wires that deliver several performance benefits, helping welders achieve strong, reliable welds every time. These include:

- Stable arc performance for smooth and efficient welding

- High metal recovery ensures better deposition and lower wastage

- Superior slag detachability reduces post-weld cleaning time

- Optimized weld bead appearance for a clean, professional finish

- AWS and ISO certified products, ensuring international quality compliance

- Consistent mechanical properties for welds that stay strong under stress

- Smooth wire feeding prevents interruptions during long welding runs

Superon’s focus on quality control ensures every spool delivers reliable output in real industrial conditions.

How to Choose the Right Flux Cored Wire for Your Welding Needs?

Selecting the correct Flux-Cored Wire is important for weld strength, performance, and productivity. Consider the following factors:

- Base metal typeMatch the wire composition to the metal you are welding, such as mild steel, stainless steel, or cast iron.

- Welding positionCertain wires perform better for vertical, overhead, or flat welding.

- Shielding gas requirementDecide between gas-shielded Flux-Cored Wire and self-shielded wire based on your working environment.

- Required weld strengthIndustrial work may demand high tensile strength and impact resistance.

- Environment and climateOutdoor projects benefit from self-shielded wires, while indoor fabrication allows the use of gas-shielded wires.

- Equipment compatibilityEnsure the wire diameter suits your welding application and feeder system.

These checks will help you select the ideal wire for strong, clean, and long-lasting results.

Why Choose Superon Technik for Flux Cored Wires?

We are a trusted name in the welding industry, known for producing high-quality Flux-Cored Wires for industrial, offshore, and food-grade applications.

- Decades of welding industry expertise

- Range of mild steel and Stainless Steel Flux Core Wire products

- Consistent quality and strong mechanical properties

- Rust-resistant, high-performance wires for demanding applications

- Nationwide distribution network

- Strong customer support for technical guidance

Our commitment to quality helps welders achieve accurate and dependable welds on every project.

-

What is Flux Cored Wire and how does it differ from solid welding wire?Flux Cored Wire contains flux inside the wire, which helps protect the weld pool. Solid wire requires external shielding gas.

-

What are the benefits of mild steel flux cored wire?It provides strong penetration, fast welding speed, and reliable weld strength on structural steel.

-

How do I choose the right Flux-Cored Wire for my welding project?Consider base metal, welding position, shielding needs, and application type.

-

Can Flux-Cored Wires be used for both manual and automated welding?Superon wires are suitable for both manual and automated welding.

-

What industries typically use Flux Cored Wires?Construction, shipbuilding, automotive, and railway use Flux Cored Wire.

-

How does Flux Cored Wire improve welding speed and quality?It offers high deposition rates, stable arcs, and deep penetration.

-

What standards do Superon’s flux cored wires comply with?Superon compiles AWS, ISO, and other relevant international welding standards.

-

Are your Flux-Cored Wires suitable for welding cast iron?Superon manufactures Flux-Cored Wires suitable for cast iron repair applications.

-

What is the difference between gas-shielded and self-shielded flux cored wire?Gas shielded wires require shielding gas, while self-shielded wires generate their own protection.

-

How to store Flux Core Wires properly to maintain quality?If you want to store your Flux Core Wire, keep it dry, sealed, and free from moisture and dust.