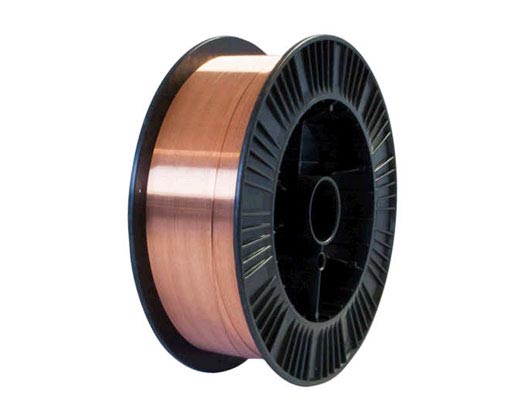

SUPERMIG 70S-6 is a copper-coated manganese silicon alloyed solid MIG welding wire developed for welding unalloyed and mild steels. This ER70S-6 welding wire is designed for use with CO2 or argon-carbon dioxide mixed shielding gases and delivers stable arc performance, clean welds, and reliable mechanical strength. It is widely used in structural fabrication and industrial manufacturing where consistent weld quality is essential.

Key Features and Benefits of Superon SUPERMIG 70S-6

Superon Technik has engineered SUPERMIG 70S-6 to meet the daily demands of fabrication shops and industrial welding applications.

Key features and benefits include:

- Excellent Weldability SUPERMIG 70S-6 offers exceptionally smooth arc characteristics with reliable and easy arc striking. This ensures welders can achieve uniform and consistent weld beads across a variety of fabrication tasks, reducing the likelihood of defects and improving overall productivity.

- Stable Arc with Minimal Spatter The wire maintains a stable arc while producing minimal spatter, enhancing the appearance of the weld and significantly reducing post-weld cleaning and finishing. This not only saves time but also improves efficiency in high-volume welding operations.

- Ultra-Clean Wire Surface SUPERMIG 70S-6 features an ultra-clean wire surface, free from drawing residues and impurities. This promotes better wire feeding, consistent arc performance, and uniform weld quality, ensuring each joint meets stringent industrial standards.

- Trouble-Free Wire Feeding Manufactured with precision control, this wire delivers steady and uninterrupted feeding, even during long welding cycles. It minimises operational downtime and supports continuous productivity in demanding structural and industrial applications.

- Good Mechanical Properties The wire produces welds with high tensile and yield strength, making it suitable for load-bearing and structural applications. Its dependable mechanical properties ensure welded joints withstand operational stresses and maintain long-term reliability.

- Low Fume Emission SUPERMIG 70S-6 generates lower levels of welding fumes, helping to create a safer and healthier working environment for operators. Reducing fumes also decreases the need for extensive ventilation and clean-up, supporting more sustainable welding operations.

- Good Radiographic Quality The wire produces welds with excellent radiographic quality, making it suitable for applications where X-ray-tested welds are required. This ensures structural integrity and compliance with critical engineering and industrial standards.

These advantages make it a preferred choice among professionals and MIG wire manufacturers in India focused on performance and consistency.

Specifications of SUPERMIG 70S-6

The table below outlines the key mechanical properties and welding conditions of ER70S-6 welding wire.

| Product Name | AWS SFA Classification | Yield Strength N/mm2 | Tensile Strength N/mm2 | Elongation A5 Percent | Impact Energy ISO V J at minus 30 C | Welding Conditions |

|---|---|---|---|---|---|---|

| SUPERMIG 70S-6 | ER 70S-6 | ≥ 450 | 510 to 640 | ≥ 26 | ≥ 47 | DC positive |

These specifications ensure dependable performance across a wide range of fabrication applications.

Properties of SUPERMIG 70S-6

SUPERMIG 70S-6 is designed to deliver consistent welding performance and reliable joint strength.

| Property | Description |

|---|---|

| Arc Stability | Smooth and stable arc during welding |

| Feeding Performance | Excellent wire feedability with minimal interruptions |

| Mechanical Strength | Produces strong and ductile weld joints |

| Spatter Control | Low spatter formation improves weld appearance |

| Surface Cleanliness | Residue-free wire supports quality welds |

| Fume Levels | Lower fume emission compared to conventional wires |

| Radiographic Quality | Suitable for applications requiring X-ray tested welds |

These properties help maintain productivity and weld consistency in industrial environments.

Applications of SUPERMIG 70S-6

This ER70S-6 welding wire is widely used across multiple industries where mild steel welding is required.

Common applications include:

- General construction and structural fabrication

- Automotive components and assemblies

- Pressure vessels and storage tanks

- Shipbuilding and marine fabrication

- Machinery manufacturing

- Heavy engineering and industrial fabrication

Its versatility makes it suitable for both production welding and repair work.

Related Products

For a complete welding solution, the following products are commonly used alongside SUPERMIG 70S-6:

- Mild steel stick electrodes

- Welding electrode holders and accessories

- Welding cables and connectors

- Industrial anti-spatter sprays

- Grinding wheels and flap discs

- Welding auxiliaries and maintenance products

These related products help improve overall welding efficiency and joint quality.