Welding Electrodes Manufacturers in India

Welding electrodes are essential consumables used to create strong, precise, and reliable welds across industrial applications. As an important product offered by any leading welding electrodes manufacturer or welding electrodes manufacturer in India, they ensure stability, durability, and superior weld quality.

About Superon Technik – Welding Electrodes Manufacturer in India

Superon Technik is a leading welding electrodes manufacturer in India, recognised for its long-standing expertise, advanced manufacturing systems, and strict adherence to ISO and AWS standards. With a strong industry presence and reliable product quality, the brand supports diverse sectors with dependable, high-performance welding solutions.

Manufacturing Excellence and Quality Assurance

Our manufacturing excellence comes from combining advanced automation with carefully monitored production systems that ensure accuracy at every step. Each welding electrode is processed through strict quality checks aligned with ISO, AWS and BIS guidelines, helping maintain consistency across batches. We also rely on modern testing equipment to evaluate arc stability, strength and overall weld performance. Backed by an active R&D setup, the process continually evolves to improve reliability and efficiency.

This approach allows us to deliver welding electrodes that offer smooth operation, reduced welding defects and dependable performance for a wide range of industrial applications.

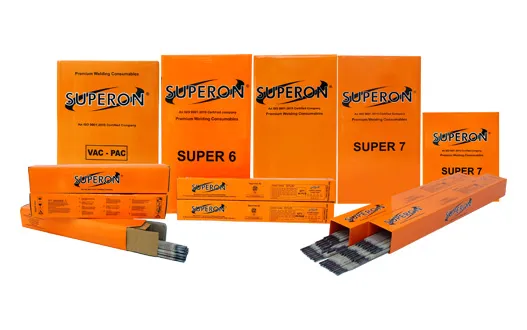

Our Comprehensive Range of Welding Electrodes

The product range includes versatile welding electrodes designed for different metals, welding positions, and operating conditions. This portfolio supports fabrication, repair, maintenance, and specialised industrial applications, ensuring dependable performance across a variety of working environments.

Stick Electrodes (Mild Steel and General Purpose)

These stick electrodes are widely used for structural fabrication, general engineering tasks, and workshop operations. Popular grades such as E6013 and E7018 ensure easy arc striking, smooth bead formation, low spatter, and compatibility with both AC and DC current. They are ideal for construction sites, fabrication shops, and everyday repair work.

Available types include:

- Carbon Steel Electrode

- Low Alloy Electrode

- Stainless Steel Electrode

- Nickel Alloy Electrode

- Copper Alloys Electrodes

- Cast Iron Electrode

- Manganese Electrodes

- Hardfacing Electrode

Maintenance and Repair Electrodes

These electrodes are engineered for rebuilding worn surfaces, strengthening components, and repairing cracks in machinery. Their strong bonding properties, high wear resistance, and long service life make them suitable for industries such as mining, cement, heavy engineering, and steel plants—where equipment is frequently exposed to abrasion and impact.

Cutting and Gouging Electrodes

The cutting and gouging range supports fast, accurate metal removal without reliance on complex cutting machinery. They help prepare joints, remove defects, and cut through various metals efficiently. These electrodes are often used in foundries, shipyards, and fabrication units that require precise edge preparation and smooth material removal.

Special Purpose Electrodes

For more specialised welding needs, the product range also includes:

- Stainless steel electrodes for corrosion-resistant applications

- Hardfacing electrodes for enhanced wear protection

- Low hydrogen electrodes for critical structural work

- Heat-resistant and pressure-resistant grades for high-temperature or high-stress conditions

These specialised variants deliver the strength, durability, and reliability required in demanding industrial environments.

Applications of Superon Welding Electrodes

Superon Welding Electrodes are widely used across industries that depend on strong, reliable and long-lasting welds. Key application areas include:

- Construction and Infrastructure– For structural fabrication, reinforcement tasks and on-site repairs.

- Shipbuilding and Marine Engineering– For components exposed to corrosion, vibration and continuous load.

- Pipelines and Oil & Gas– For high-pressure pipelines, tanks and critical joint preparation.

- General Fabrication and Workshops– For daily fabrication, assembly and routine maintenance work.

- Automotive and Heavy Machinery– For chassis fabrication, rebuilding worn components and welding high-strength parts.

- Mining, Steel and Cement Industries– For repairing equipment and restoring heavy-wear surfaces.

These Welding Electrodes provide stable arcs, strong bonding and dependable weld integrity, even under demanding industrial conditions.

Innovation and R&D in Welding Consumables

Superon Technik focuses strongly on advancing its Welding Consumables through continuous research and development. Key innovation areas include:- Improved Electrode Coatings that offer smoother weld flow and enhanced durability.

- Better Arc Stability for consistent performance across varying welding conditions.

- Low-Spatter Formulations that support cleaner welds and reduced post-weld finishing.

- Eco-Friendly Chemistries are designed to lower fume generation and improve operator safety.

- Precision-Driven Testing to refine metallurgical properties and optimise electrode behaviour.

- Material and Process Upgrades that improve ease of use, weld quality and long-term reliability.

These advancements help ensure Superon Welding Consumables stay aligned with evolving industrial needs.

Why Choose Superon as Your Welding Electrodes Manufacturer?

Choosing Superon as your preferred Welding Electrodes Manufacturer means working with a brand that prioritises quality, reliability and customer value. The company combines strong manufacturing capability with service-focused advantages that support fabricators across India.

Key reasons to choose Superon include:

- Consistent Quality– Every electrode is produced with rigorous checks, ensuring dependable weld performance and stress-free operations.

- Transparent Pricing– A one-country-one-price policy helps maintain fairness for distributors and buyers across India.

- Easy Availability– Multiple purchasing options and wide distribution ensure effortless access to Welding Electrodes when needed.

- All-in-One Solutions– A comprehensive range of welding consumables reduces dependence on multiple suppliers.

- Superior Performance– Electrodes are designed for strong bonding, stable arcs and long-lasting weld strength.

- High Productivity– Efficient formulations help save time, enhance equipment life and reduce operational downtime.

- Compliance with International Standards– Adherence to ISO, AWS and BIS guidelines ensures safety and credibility.

- Wide Product Range– Options suited for fabrication, repair, maintenance and specialised industrial tasks.

- Technical Support and After-Sales Assistance– Teams help customers choose the right electrode and troubleshoot challenges.

- Reliable Pan-India Delivery– A strong supply chain ensures timely and consistent product availability.

- Trusted Across Industries– Used by sectors such as construction, pipelines, automotive, shipbuilding and heavy engineering.

Superon continues to build long-term partnerships by offering Welding Electrodes that deliver strength, precision and cost-effective performance for every application.

FAQs

1. What types of Welding Electrodes does Superon manufacture?

Superon manufactures a comprehensive range of Welding Electrodes, including mild steel, stainless steel, hardfacing, repair and maintenance, and special-purpose electrodes designed for different metals and applications.

2. Which industries benefit from Superon Welding Electrodes?

A wide range of sectors rely on these electrodes, including construction, automotive, shipbuilding, pipelines, railways, fabrication workshops, power plants, mining, and heavy engineering.

3. How do I choose the right Welding Electrode for my project?

Selection depends on several factors — the base metal, welding position, required strength, material thickness, and the working environment. Superon also provides technical guidance to help users select the most suitable electrode.

4. What international standards do Superon Welding Electrodes comply with?

The electrodes are manufactured in line with ISO, AWS, BIS, and other globally recognised welding standards to ensure consistency, safety, and reliability.

5. How should Welding Electrodes be stored to maintain quality?

They should be kept in a dry, moisture-free environment, ideally in sealed packaging. Low-hydrogen electrodes may require oven storage to prevent moisture absorption.

6. Does Superon offer customised Welding Electrode solutions?

Yes. Superon can develop customised electrodes based on specific applications, material requirements, or performance expectations.

7. What makes Superon Welding Electrodes superior to competitors?

Their strength lies in advanced coating technology, strict quality testing, consistent arc performance, stable bonding, and proven reliability across tough industrial conditions.

Contact Us for Welding Electrodes in India

If you’d like to know more about Superon’s complete range of Welding Electrodes or request a quotation, our team is ready to help. Superon offers strong distribution support across India, global supply capabilities, and detailed product catalogues to help you choose the right solution for your needs.