If you are new to welding, you may wonder what welding electrodes are. An electrode is a conductor that carries electrical current to the welding arc and often provides filler material to join metals together. Electrodes are essential for creating strong, durable weld joints. There are two main categories: consumable electrodes that melt to become part of the weld, and non-consumable electrodes that remain intact, offering precision and control.

Choosing the right electrode is crucial as it affects weld quality, strength, and the overall success of your project.

How Welding Electrodes Work?

Welding electrodes conduct electrical current to generate an arc, producing heat sufficient to melt metals. Consumable electrodes melt during this process, depositing filler material into the joint. Electrode coatings produce shielding gases and slag that protect the weld from contamination. Arc stability and coating composition influence penetration, weld strength, and overall quality.

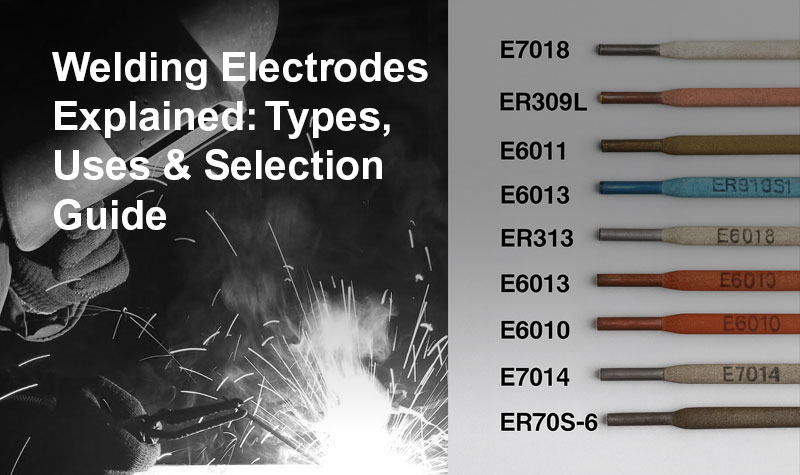

Types of Electrodes in Welding

There are various types of electrodes, each designed for specific applications and metals. Choosing the right type of electrodes ensures strong, reliable welds.

Consumable Electrodes

Consumable electrodes melt during welding to form the filler material. Examples include:

- SMAW sticks – ideal for construction, repair, and structural projects

- MIG/MAG wires – suitable for automated welding and faster production

- Flux-cored wires – used in outdoor or heavy-duty industrial applications

Non-Consumable Electrodes

Tungsten electrodes used in TIG welding are non-consumable, meaning they do not melt. They provide high precision and minimal contamination, making them perfect for stainless steel fabrication or thin metal projects.

Bare Electrodes

Bare electrodes do not have coatings and are used in applications that need minimal shielding. Some industrial repair projects still rely on bare electrodes.

Coated Electrodes

Electrode coatings influence arc stability, penetration, and slag formation. Here’s a quick summary:

| Coating Type | Characteristics | Applications |

| Rutile | Smooth arc, easy slag removal | General fabrication |

| Cellulose | Deep penetration, fast freeze | Pipeline welding |

| Low hydrogen | Strong weld, moderate penetration | Heavy engineering |

| Low hydrogen Iron Powder | High deposition, faster welding | Structural steel |

Welding Electrodes by Material Type

Electrodes are also categorised based on the type of metal they are designed for. Here’s an overview:

| Material | Strength | Corrosion Resistance | Typical Use |

| Mild Steel | High | Low | Structural steel |

| Stainless Steel | Moderate | High | Kitchen equipment, railings |

| Nickel Alloy | Very High | Very High | Chemical plants |

| Cast Iron | Medium | Moderate | Repair works |

Selecting the Right Electrode for Your Welding Project

Understanding welding electrodes is only the first step. Selecting the right electrode ensures strong, reliable welds. Consider the following factors:

- Base metal type: Identify whether you are welding mild steel, stainless steel, nickel alloy, or another metal. Different metals need specific electrodes.

- Welding position: Flat, vertical, or overhead positions affect electrode performance and ease of use.

- Current type compatibility: Ensure the electrode matches AC or DC welding for proper arc stability.

- Joint design: Consider weld thickness and type to select the correct electrode size and type.

Quick checklist for welders:

- Metal type confirmed

- Welding position checked

- Current type compatible

- Joint design assessed

Following these steps reduces common welding problems such as porosity, weak joints, and slag inclusion, and ensures consistent, high-quality results.

Welding Electrode Standards and Markings

Electrode standards, such as AWS (American Welding Society) and IS (Indian Standards), help welders choose reliable and safe electrodes for their projects. These classifications indicate tensile strength, welding position, coating type, and overall usability.

Key points to consider:

- Electrode code: For example, E6013 – ‘E’ stands for electrode, 60 indicates tensile strength in ksi, 1 shows all-position suitability, and 3 refers to the coating type.

- Strength: Higher numbers indicate stronger weld deposits.

- Position: Codes show whether the electrode can be used flat, vertical, or overhead.

- Coating type: Determines arc stability, penetration, and slag formation.

Reference table for common electrodes:

| Code | Strength (ksi) | Position | Coating Type |

| E6013 | 60 | All | Rutile |

| E7018 | 70 | All | Low-hydrogen |

Following standards ensures consistent weld quality, reduces defects, and helps select the most suitable electrodes for any welding project.

Proper Storage and Handling of Welding Electrodes

Correct storage is essential for maintaining electrode quality and preventing issues such as porosity, hydrogen cracks, and poor arc performance. Moisture is the biggest risk, as damp electrodes can damage the weld and compromise strength.

Best practices for storage and handling:

- Keep electrodes in sealed, moisture-free packaging until use.

- Store opened electrodes in industrial electrode ovens at recommended temperatures to prevent moisture absorption.

- Avoid placing electrodes directly on concrete floors or in humid environments.

- Reheat low-hydrogen electrodes when required, following manufacturer guidelines.

- Use clean, dry gloves when handling to prevent contamination.

Typical storage temperatures:

- Low-hydrogen electrodes: 250–300°C (in ovens)

- General-purpose electrodes: Room temperature in dry conditions

Following these measures ensures consistent performance, stable arcs, and defect-free welds on site.

Common Welding Electrode Problems and How to Avoid Them

Even experienced welders encounter electrode-related issues, but most problems can be prevented with proper selection, storage, and technique.

Typical defects include:

- Porosity: Often caused by moisture in electrodes or surface contaminants.

- Slag inclusion: Results from incorrect angle or inadequate cleaning between passes.

- Arc instability: Linked to damaged coatings, incorrect current settings, or poor-quality electrodes.

- Coating damage: Happens due to rough handling or improper storage.

How to avoid these issues:

- Ensure electrodes are dry and properly stored before use.

- Clean the base metal thoroughly to remove rust, oil, or paint.

- Set the correct current according to electrode specifications.

- Maintain proper welding angles and travel speed.

- Inspect electrodes for cracks or broken coatings.

Using suitable, well-maintained electrodes significantly reduces defects and leads to cleaner, stronger welds.

Advantages of Using High Quality Electrodes From Superon Technik

Superon Technik is recognised across India for manufacturing high-performance welding consumables designed to deliver consistent, reliable results. With a strong focus on quality and accessibility, Superon supports fabricators, construction companies, and heavy engineering industries with products they can trust.

Why welders choose Superon:

- Consistent arc stability: Ensures smoother welding and better control.

- Low spatter: Reduces clean-up time and improves weld appearance.

- Strong, reliable weld deposits: Suitable for demanding industrial applications.

- High-quality coatings: Provide excellent arc initiation and protection against contamination.

- Nationwide availability: Easy access to products anywhere in India.

Where Superon makes an impact:

- Fabrication workshops achieve uniform weld quality.

- Construction sites benefit from dependable electrodes in varied conditions.

- Heavy engineering units rely on strength and durability for critical joints.

Superon’s focus on performance, consistency, and accessibility makes it a trusted partner for welding professionals across the country.

FAQ

1. What is the difference between consumable and non-consumable electrodes?

Consumable electrodes melt during welding and supply the filler metal that forms the joint. Non-consumable electrodes, such as tungsten, do not melt and are mainly used for precision welding.

2. How do electrode coatings affect weld quality?

The coating plays a big role in stabilising the arc, improving penetration, and keeping the weld clean by protecting it from contaminants.

3. Can the same electrode be used for AC and DC welding?

Some electrodes are compatible with both AC and DC, but others are designed for a specific current type. It is always best to check the manufacturer’s specifications.

4. How do I prevent electrode moisture damage on site?

Keep electrodes in dry storage, use sealed containers, and rely on electrode ovens when needed. This helps avoid porosity and weak welds.

5. Which electrode type is best for stainless steel welding?

Electrodes with a stainless steel composition that matches the base metal give the best results and ensure corrosion resistance.

6. What do electrode classification numbers mean?

These numbers tell you the tensile strength, suitable welding positions, coating type, and current compatibility of the electrode.