Welding is a key process in construction, manufacturing and repair work. The strength and quality of a weld depend not just on technique but also on using the right welding rod. One common mistake is selecting a rod that is too thick or too thin for the job. This can lead to weak joints, poor penetration or even cracking. Understanding how to choose the correct welding rod size is essential for producing strong, reliable and durable welds. A welding rod size chart can make this process much easier and more precise.

What Welding Rod Size Means

The size of a welding rod, usually its diameter, determines how much filler metal is added to the weld and how much heat is needed. A larger rod carries more metal and requires higher amperage, producing deeper penetration and a wider weld bead. Smaller rods are better suited for thinner materials and provide better control for fine welds.

Using the wrong rod size can compromise the weld quality. For example, a rod that is too thick may burn through thin metal, while a rod that is too small might not create enough penetration for a strong joint. Understanding welding electrode sizes is essential to match the rod with the base metal, welding current and position.

Standard Welding Rod Sizes and Their Uses

There are several standard welding rod sizes, each suited for specific applications:

- 1.6 mm rods: Ideal for thin metals, sheet metal work and precise welding tasks.

- 2.0 mm rods: Suitable for slightly thicker metals and small fabrication projects.

- 2.5 mm rods: Common for general fabrication and medium-thickness steel.

- 3.2 mm rods: Used for thicker metals, heavy fabrication and industrial applications.

- 4.0 mm rods: Designed for very thick metals and high-strength structural welding.

- 5.0 mm rods: Reserved for very heavy structural steel work and large industrial projects.

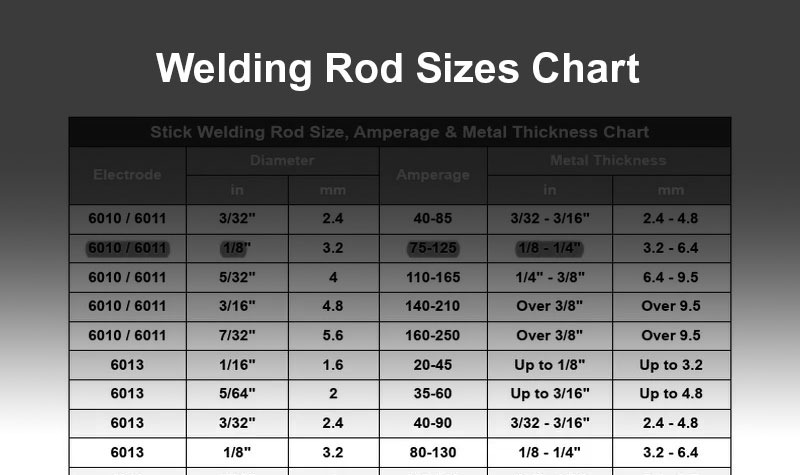

A welding rod size chart helps visualise which rod is suitable for a particular metal thickness, current range and welding task, making selection simpler for both beginners and experienced welders.

Factors to Consider When Choosing a Welding Rod Size

Several factors affect which welding rod size is appropriate:

- Base metal thickness: Thin metals require smaller rods for controlled heat input. Thicker metals need larger rods for deep penetration.

- Welding current type: Some rods perform better with AC, while others perform better with DC. Ensure your rod size matches your current source.

- Welding position: Flat, vertical or overhead welding affects rod choice. Some rod sizes are easier to handle in certain positions.

- Type of welding rod: Low-hydrogen rods, stainless steel rods and mild steel rods have different characteristics and size recommendations.

- Environmental conditions: Outdoor work, moisture or extreme temperatures may require specific rod sizes and types to maintain weld quality.

Considering these factors ensures better control, stronger welds and fewer defects.

Using a Welding Rod Size Chart

A welding rod size chart is the easiest way to match rod diameter to your project needs. Here is a simple reference:

|

Rod Size (mm) |

Base Metal Thickness (mm) |

Typical Applications |

|

1.6 |

0.5 – 2 |

Sheet metal, thin fabrication |

|

2.0 |

1 – 3 |

Light structural work, repairs |

|

2.5 |

2 – 5 |

General fabrication, medium steel |

|

3.2 |

3 – 10 |

Thick metals, industrial work |

|

4.0 |

8 – 15 |

Heavy fabrication, structural steel |

|

5.0 |

12 – 25 |

Very thick metals, large-scale projects |

This chart helps select the correct rod without guesswork. It also makes it easier to adjust the amperage based on the rod size for optimal results.

Tips for Selecting the Right Welding Rod Size

Choosing the correct welding rod size can be confusing, but following a few simple guidelines helps ensure strong, clean, and durable welds for any project.

- Match rod size to metal thickness: Smaller rods for thin sheets, larger rods for thicker metals.

- Adjust amperage: Each rod size has a recommended current range. Following this ensures proper penetration and weld strength.

- Check the rod type: Low-hydrogen rods work best for thick, structural steel, while stainless steel rods are suited for corrosion-resistant projects.

- Avoid common mistakes: Using rods that are too large or too small can cause spatter, weak joints or burn-through.

- Follow manufacturer guidelines: Always check packaging for current range, welding position and recommended applications.

Superon Technik provides welding electrodes that deliver consistent arc stability, low hydrogen content and uniform weld quality. Their electrodes are designed for industrial and structural projects, making them reliable choices when following a welding rod size chart.

Common Mistakes to Avoid

Even experienced welders sometimes make rod selection errors. Common mistakes include:

- Using a general-purpose rod for all projects, which may weaken the weld

- Failing to match the rod size with the metal thickness or the welding position

- Ignoring the recommended current ranges for each rod size

- Improper storage, leading to moisture absorption and reduced rod performance

Avoiding these mistakes ensures stronger welds and reduces the risk of rework or failure. Superon Technik welding electrodes are engineered to minimise these issues, providing consistent results and reducing common rod-selection errors.

Why Rod Quality Matters

Choosing the right rod size is important, but the quality of the welding rod is equally critical. High-quality rods deliver a stable arc, consistent penetration and minimal spatter, making the welding process smoother and more reliable. Poor-quality rods can cause weak joints, inconsistent welds and wasted material. Using premium welding electrodes ensures predictable results, stronger joints and better overall efficiency, reducing rework and saving time, effort and costs on every welding project.

Conclusion

Selecting the correct welding rod size is crucial for achieving strong, durable and defect-free welds. Using a welding rod size chart helps match rod diameter to metal thickness, current and welding position, making selection simpler and more accurate. Proper rod selection reduces failures, saves time and makes welding a more efficient and reliable process.