Surface defects can compromise the strength, safety, and service life of welded and fabricated components. Early detection of such defects is therefore critical in fabrication, manufacturing, and maintenance environments. Among various non-destructive inspection methods, visible dye penetrant testing is one of the most accessible and widely used techniques for identifying surface-breaking flaws in non-porous materials. Its simplicity, reliability, and visual clarity make it especially suitable for workshops, job sites, and quality control environments.

What Is Visible Dye Penetrant Testing?

Dye penetrant testing, also referred to as liquid penetrant inspection, is a non-destructive inspection method used to locate surface-breaking defects in solid, non-porous materials. The method relies on capillary action, allowing a coloured liquid penetrant to enter fine cracks, seams, laps, porosity, and other surface discontinuities.

After the excess penetrant is removed, a developer is applied. The developer draws penetrants trapped inside defects back to the surface, forming clear visual indications that can be evaluated under normal white light. Because the material remains undamaged, the method is widely used for inspection during fabrication, maintenance, and in-service examinations.

Where To Use Dye Penetrant Testing?

Visible dye penetrant testing is commonly applied across manufacturing and maintenance environments, including:

- Post-weld inspection

- Casting and forging examination

- Pipeline and pressure component inspection

- Machined part quality checks

- Maintenance inspections for in-service components

Its portability and minimal equipment requirement make it suitable for both workshop-based inspections and on-site evaluation tasks.

Materials Suitable for Dye Penetrant Testing

Dye-penetrant testing is only applicable to non-porous materials. At Superon Technik, we recommend this method for the following materials:

- Aluminium

- Stainless steel

- Carbon steel

- Brass

- Copper

- Cast iron

- Certain ceramics

- Selected plastics

Porous materials are not suitable because the penetrant spreads to the surface, creating false indications.

How to Use Visible Dye Penetrant Testing Step by Step?

Understanding how to use dye penetrant test procedures correctly is essential for reliable inspection results.

Step 1: Surface Cleaning

All oil, grease, rust, paint, dirt, and moisture must be removed from the inspection area. The surface should be thoroughly cleaned with a suitable cleaner and allowed to dry completely.

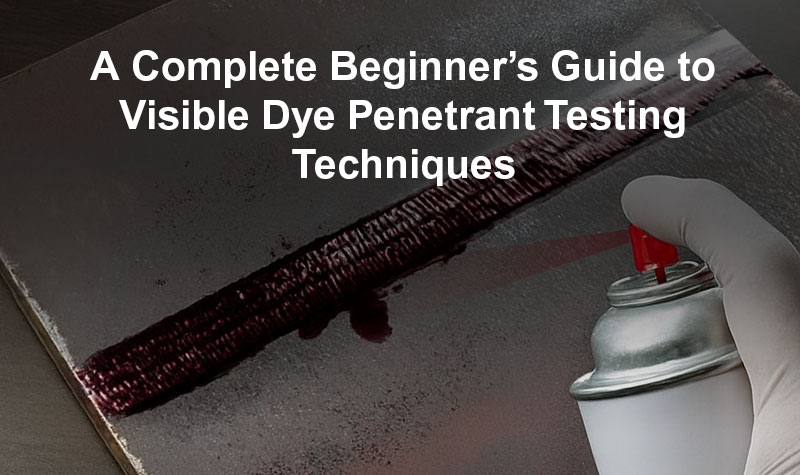

Step 2: Applying the Penetrant

A visible red dye penetrant is applied evenly by spraying, brushing, or dipping. The penetrant is allowed to dwell on the surface, typically for 10–30 minutes depending on defect size and material type.

Step 3: Removing Excess Penetrant

Excess penetrant is gently removed using a clean, dry cloth. If required, a lightly moistened cloth may be used. The surface must not be flushed, as this may remove penetrant trapped inside defects.

Step 4: Applying the Developer

A thin, even layer of developer is applied. The developer draws penetrant out of the defects and spreads it on the surface, creating visible indications.

Step 5: Inspection and Interpretation

Inspection is carried out under adequate white light. Defects appear as red lines, dots, or clusters on a white background. The size, shape, and distribution of these indications help determine defect severity.

Step 6: Post-Cleaning

After inspection, the surface is thoroughly cleaned to remove all penetrant and developer residues before further processing or service.

Advantages of Visible Dye Penetrant Testing

Dye Penetrant Testing is recommended because it offers several practical advantages:

High Sensitivity To Fine Surface Cracks

The method can detect very small surface-breaking cracks, pinholes, and porosity that are not visible to the naked eye. This high sensitivity allows early identification of defects before they grow into major failures, supporting better preventive maintenance and quality control.

Simple And Easy To Perform

The testing procedure is straightforward and does not require complex machinery or highly specialised operators. With basic training and standard consumables, inspections can be carried out efficiently in workshops and on-site locations.

Low Inspection Cost

Compared to many other non-destructive testing techniques, dye penetrant testing involves minimal equipment and consumable costs. This makes it a cost-effective option for regular inspections, production checks, and maintenance activities.

Clear And Visible Results

Defects appear as clearly visible coloured indications on the surface, making interpretation easier and reducing the risk of overlooking critical flaws. This improves inspection accuracy and supports reliable decision-making.

Suitable For Complex Shapes

The method works well on components with irregular profiles, curves, grooves, and varying thicknesses. It allows thorough inspection of parts that are difficult to examine with conventional testing techniques.

Works On Non-Magnetic Materials

Dye penetrant testing is effective on non-magnetic metals and alloys such as stainless steel, aluminium, copper, and brass. This makes it widely applicable across fabrication, processing, and maintenance environments where magnetic testing cannot be used.

These benefits make it a reliable inspection method for routine and critical applications.

Limitations and Safety Guidelines

This method detects only surface-breaking defects. Subsurface discontinuities cannot be identified. The surface must be accessible, smooth, and non-porous for accurate results.

Penetrants, cleaners, and developers are chemical products and must be handled with proper ventilation, protective equipment, and responsible disposal practices.

Common Errors to Avoid During DPI

To maintain inspection accuracy, we avoid common mistakes such as:

- Incomplete surface cleaning

- Insufficient penetrant dwell time

- Excessive cleaning during penetrant removal

- Over-applicationOver application of the developer

- Poor lighting during inspection

Following the correct procedure step by step helps prevent these issues.

Why Visible Dye Penetrant Testing Is Recommended?

Visible dye penetrant testing remains one of the most effective non-destructive inspection methods we use. It combines simplicity, accuracy, and cost efficiency. The method delivers fast results, requires minimal equipment, and provides clear visual confirmation of surface defects.

Conclusion

Visible Dye Penetrant Testing remains a dependable non-destructive inspection technique for identifying surface defects in critical components. Accurate surface preparation, controlled application, and proper inspection procedures ensure consistent, reliable results across fabrication, welding, and maintenance operations.

For high-performance penetrants, cleaners, developers, and complete inspection solutions, explore Superon Technik’s range of NDT consumables designed to deliver clarity, reliability, and consistency in every inspection process.