Stainless steel is the material of choice for food processing, architecture, and beyond because it's tough, resistant to corrosion, and boasts a shiny, high-tech appearance. But any welder who's had experience with stainless steel is probably intimately familiar with how pretty and durable it looks, but how slightly high-maintenance it is to clean up after welding.

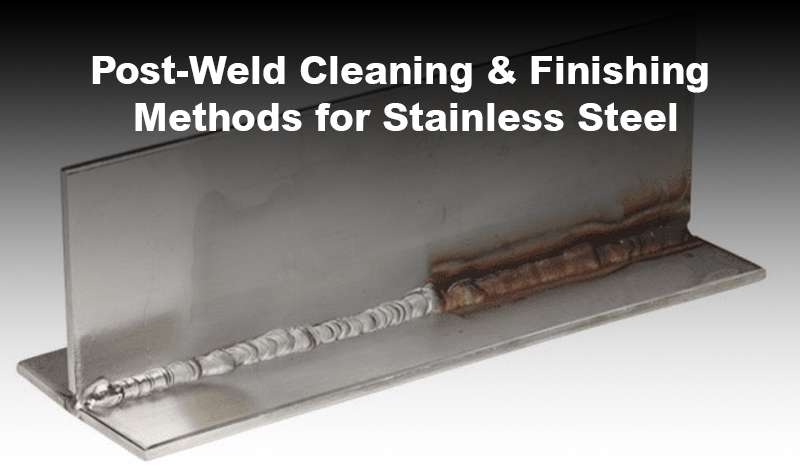

Stainless steel is not quite so horribly "stainless" once it's been welded. You're typically left with heat tint, discolouration, spatter, oxide layers, or burn edges. These imperfections don't just make the metal less-than-gorgeous-appearing—these very same imperfections weaken corrosion resistance and surface cleanliness, and this matters to industries like pharmaceutical, dairy, or marine.

S,o how do you achieve that great shine and life stainless steel possesses? That is where post-weld cleaning and finishing come into play.

In this article, here, we're going to talk about why post-weld cleaning is so vital, go over some various techniques in cleaning and finishing, and assist you with determining what will best suit your particular stainless steel project.

Why Post-Weld Cleaning Is So Important?

Let us begin with the most self-evident question: why clean stainless steel upon welding, anyway?

- Restore Corrosion Resistance: Stainless steel develops a thin layer of chromium oxide on the surface. It makes the material rust-resistant. Welding, grinding, or even holding destroys the layer. Cleaning rejuvenates the passive layer and makes the steel corrosion-resistant.

- Remove Heat Tint and Oxides: Welding produces heat, which forms discoloration—heat tint—that is darker than skin. It is an indication the protective oxide layer has been disrupted. It will rust and must be treated.

- Enhance Appearance: When appearance is critical in industries such as building or domestic goods, there must be a clean even finish. Discoloration, spatter, and scratch must all be eliminated.

- Comply with Hygiene Requirements: Having food, drug, and beverage close by, cleanliness is impossible. Bacteria can be slowed down on rough surfaces or near welds due to grime. The only smooth, clean surfaces that are available for use are these.

What Happens to Stainless Steel When Welded?

Before we move on to the cleaning section, let's discuss what happens to stainless steel when welded. Welding stainless steel puts it at high temperatures. This results in:

- Oxidation (heat tint)

- Surface contamination

- Near-weld area distortion

- Welding spatter and slag deposits

All of these compromise the corrosion-resistance coating and cause a rough finish. The level of contamination will vary with the type of welding process (TIG, MIG, Stick), the steel grade, the shielding gas, and the operator's skill level.

Step-by-Step Post-Weld Finishing and Cleaning Process

Now, let us discuss how stainless steel is restored after welding. There are typically three post-weld cleaning methods:

- Mechanical Cleaning

- Chemical Cleaning (Pickling and Passivation)

- Finishing and Polishing

They all have an application, and you might use one or more based on your ultimate purpose.

1. Mechanical Cleaning: The Beginning

Mechanical cleaning is the physical removal of surface dirt by abrasion or by machinery.

Common Mechanical Methods:

a. Wire Brushing

- Uses a stainless steel wire brush.

- Cleaning the surface grime and superficial oxidation from the surface.

- It is recommended to always use a stainless steel brush to prevent cross-contamination.

b. Grinding

- Reform major defects and weld beads.

- Use stainless steel grind wheels or flap discs.

- Do not over-grind to compromise the material or create rough surfaces.

c. Abrasive Blasting (Glass Bead Blasting or Sandblasting)

- Removes surface blemishes by blasting the surface with media.

- Glass bead blasting is light and suitable for cosmetic finishes.

- Not appropriate for hygienic use if not properly cleaned up afterwards.

d. Scotch-Brite or Non-Woven Pads

- Used on smooth and blended weld surfaces.

- Creates a satin or brushed finish, which is suitable for architectural stainless.

Recommendations:

- Avoid carbon steel tools or abrasives for use on stainless steel.

- Clean tools always before resuming metal-to-metal work.

- Use a smooth stroke to prevent streaking or mottled finishes.

2. Chemical Cleaning: Pickling and Passivation

Mechanical cleaning is wonderful, but it does not restore stainless steel's corrosion resistance. That's when chemical cleaning comes into the picture.

What Is Pickling?

Pickling is the treatment of an object with acid solutions to remove weld scale, oxides, and heat colour produced during welding. Pickling is stronger than mechanical cleaning and paves the way for passivation.

Methods of Pickling:

- Pickling Paste or Gel: Direct application on the weld area.

- Pickling Spray: Large surfaces.

- Immersion Pickling: Soaking of the small components in an acid tank.

Most commonly used acids:

- Nitric acid + hydrofluoric acid

What Is Passivation?

Passivation is the restoration of the protective chromium oxide film on stainless steel. Following pickling or mechanical machining, free iron is stripped away by a nitric or citric acid bath, which accelerates the formation of a stable, protective film.

Passivation Procedures:

- Immersion in a nitric or citric acid bath.

- Spraying or wiping the passivation solution.

- Rinse thoroughly and dry after treatment.

Safety Reminders:

- Wear gloves, safety glasses, and proper PPE at all times.

- Use a well-ventilated room or fume hood.

- Dispose of chemicals according to local regulations.

3. Electrochemical Cleaning: The Modern Touch

Electrochemical cleaning is becoming increasingly popular for stainless steel processing after post-weld finishing, particularly for products where high cleanliness is necessary.

What Is Electrochemical Cleaning?

It's an electric current and an electrolyte used in a process to strip grime from the weld spot. A brush or wand has a power source that's immersed in an acid bath and put on the weld.

Advantages:

- Quick and accurate

- Restores corrosion protection

- Gives a shiny, buffed look

- Less environmentally harsh than old-fashioned pickling

Typically Applied To:

- Fabrication of food-grade stainless steel

- Pharmaceutical-grade equipment

- Architectural stainless steel buildings

4. Final Finishing and Polishing

The final finish is applied after cleaning and passivating the weld. The desired finish type will depend on the end use.

Typical Finishes:

a. Brushed Finish (No. 4)

- Still common on cookware and decorations.

- It is done by the application of abrasive belts or pads.

- Provides an even, flat finish.

b. Mirror Finish (No. 8)

- High-gloss appearance. Mirror-like shine.

- Requires sequential polishing operations with progressively finer compounds.

- Time-consuming and best avoided by highly exposed pieces.

c. Satin Finish

- It can be referred to as a low-gloss, smooth finish.

- Low upkeep and simple to clean.

- Frequently used in architectural applications.

Equipment and Materials:

- Buffing wheels

- Polishing compounds

- Sandpaper (utilise coarse to fine grit first)

- Final blending of non-woven pads

Cleaning Stainless Steel Welds in Special Environments

Based on the environment where the stainless steel will be applied, how it is cleaned differs. Let's look at a few examples:

1. Food Industry

- Needs to be clean on standards such as 3-A or FDA.

- Crevices, pits, and roughness have to be removed from all surfaces.

- Electrochemical cleaning and passivation are applied universally.

2. Marine Application

- Additional protection against corrosion is needed when in contact with saltwater.

- Welds need to be properly passivated and sealed.

- Sealants or coatings can be applied for additional protection.

3. Pharmaceutical Equipment

- Cleanability and sterilizability are crucial.

- Mirror finish or electropolishing may be required.

- Documentation and validation of the clean is standard.

Preventable Common Errors

Even experienced fabricators will be guilty of post-weld cleaning errors. Some to steer clear of are:

- Carbon steel brushes on stainless – rust contamination.

- Omission of passivation in the process exposes the surface to corrosion.

- Too abrasive abrasives can destroy the finish or damage the surface.

- Inadequate rinsing after chemical cleaning leaves acid residue.

- Neglecting to follow up on pickling – a cleaned surface is not passivated.

Eco-Friendly and Safer Alternatives

Traditional pickling uses corrosive acids such as hydrofluoric acid, which are toxic. Safer alternatives and more environmentally friendly processes, such as electrolyte cleaning, citric acid passivation, and mechanical finishing, are available.

Green Tips:

- Replace nitric/hydrofluoric acid with citric acid wherever feasible.

- Reuse and dispose of waste and rinse water appropriately.

- Minimise overspray or spillage of chemical treatments.

Conclusion: The Secret to Long-Lasting, Clean Stainless Steel

Welding stainless steel is only half the story—real beauty (and performance) follows in proper post-weld cleaning and finishing.

By selecting and using the right mechanical, chemical, or electrochemical process, you will be able to:

- Maximise the lifespan of your stainless steel products

- Increase corrosion resistance

- Comply with safety and hygiene requirements

- Improve the finished appearance of your work

Whatever you're producing - industrial tanks, decorative railings, or life-saving medical devices - the time and effort of post-weld cleaning is money in the bank with payback that will earn dividends down the line.

The next time you complete a weld, don't turn around. Clean it. Passivate it. Polish it. That's how stainless steel becomes stainless steel.

Also Read: Welding Excellence - Superon 308L Stainless Steel Electrode